ZKJ Series Linear Vibrating Screen

About the ZKJ series screen

ZKJ series linear vibrating screen is a new-model of the original ZKB screen. It’s developed independently by Kunming Ciba Mining Machinery Co., Ltd. It’s applicable to ore mining, coal mining, infrastructure material production, energy production, and the chemical industry, in processes such as material classification, desliming, dewatering, and medium removal.

Since the screen is vibrating linearly, materials are in a slanted upward motion with an angle of 30-60 degrees. The screening ration is high due to such motions, thus the separation efficiency is increased accordingly. The linear vibrating screen is suitable for separation of coarse materials and dewatering process.

The exciter crossbeam is assembled after complete stress removal annealing treatment. The crossbeam is the key to the performance of a screen. This series of screens is designed to be welded to meet relevant special requirements. The crossbeam of the exciter is in cylinder- or box-shaped beam structure which is lighter, stronger, and with high flexural and torsional resistances. Such designs of the crossbeam increase its endurance to excitational forces generated by the exciter.

The vibration motor functions as the source of vibration. It’s advantageous in high energy efficiency, high yields, simple structure, and easy maintenance and repair.

Selection guide for ZKJ series linear vibrating screen

- Single- and double-layer screens are available.

- Materials of the deck are available in stainless steel, polyurethane or composite of stainless steel and polyurethane.

- Installation methods are available in upslope or downslope at an angle of -5 to 5 degrees. Upslope installation is for incline screens that the outlet is higher than the inlet. Downslope installation is for incline screens that the inlet is higher than the outlet.

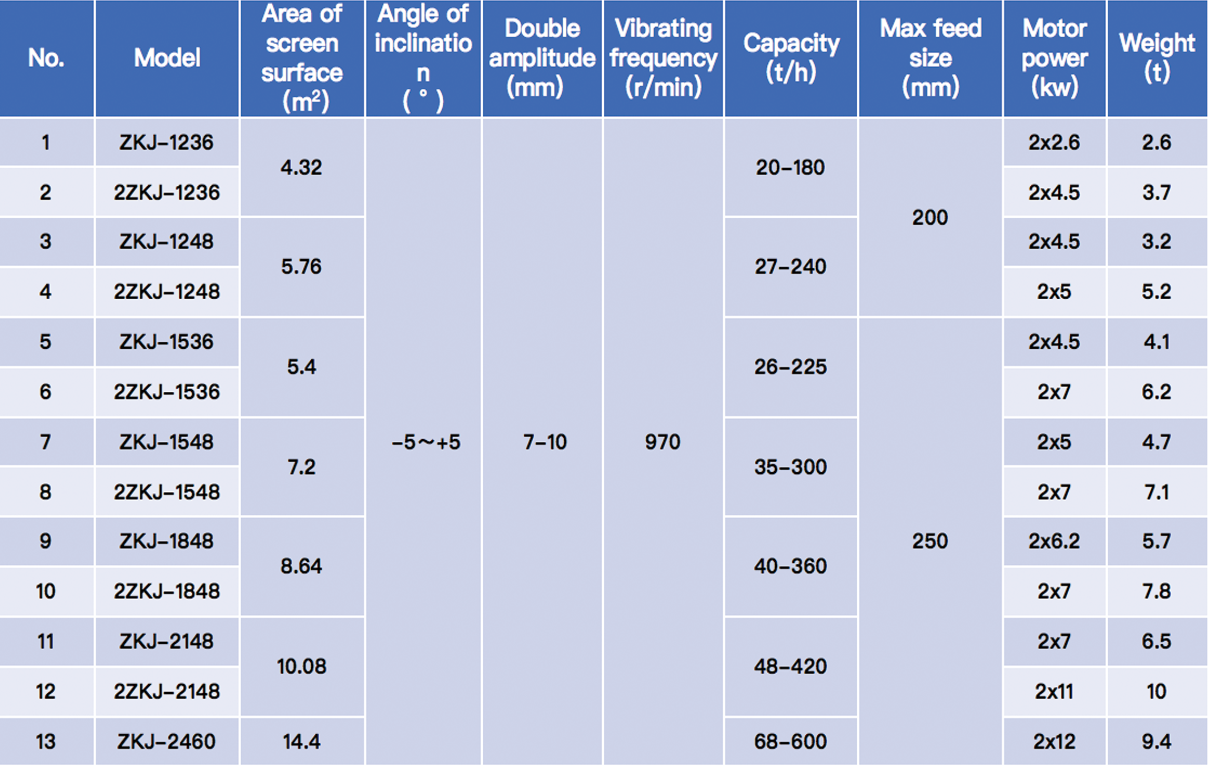

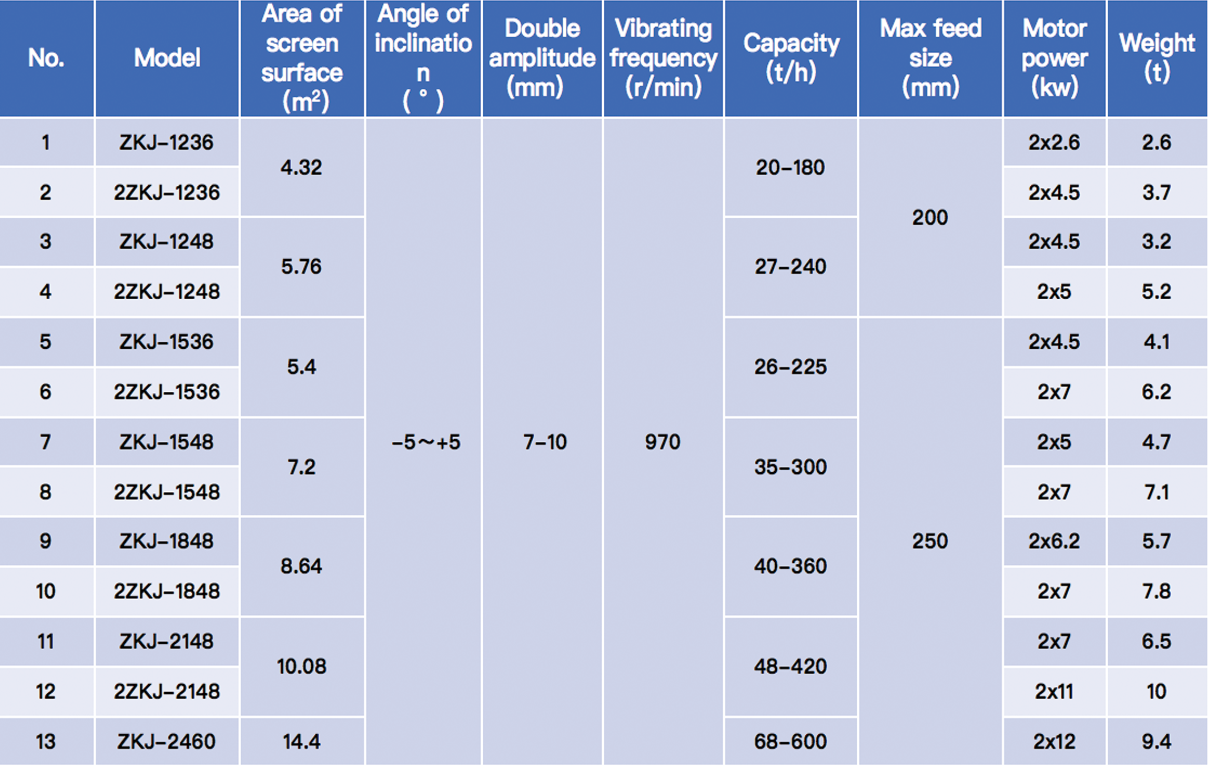

Main Technical Parameters of ZKJ Series Linear Vibrating Screen

Note:

1. Parameters in the table may vary based on parts selected and distinct customer requirements. Actual parameters in final drawings prevail.

2. The capacity varies on the basis of materials, feed sizes and other factors.

Contact Us

If our product don't have your specifications,

our custom shop can give you an unique solution to meet your needs

Custom Shop