GZT Series Grizzly Feeder

About the GZT series feeder

GZT series grizzly feeder is mainly used for uniform, regular and continuous feeding of lumpy materials and rough screening during feeding. It can be started up with materials loaded. It’s widely used in crushing-screening joint equipment in metallurgy industry, coal mining, ore mining, infrastructure material production, and chemical industry.

The inlet of this series of feeder has a high-strength framework structure which is durable and resistant to impact of large-size materials. Base of the vibrator and the sideboard are connected with bolts. Position of the vibrator can be adjusted to meet customers’ requirements and to achieve the best performance. The outlet is made of casted alloy bars to perform rough screening processes without clogging the opening and to ensure a longer service life. The vibration reduction springs are made of high quality spring steels to ensure good elasticity and vibration reduction.

With a flexible coupling, the motor will not be affected by the vibration of the feeder. The screen has several advantages including non-demanding installation, stable operation, and fine vibration locus.

Selection guide for GZT series grizzly feeder

- Single- and double-layer screens are available.

- Materials of the deck are available in stainless steel, polyurethane or composite of stainless steel and polyurethane.

- Installation methods are available in upslope or downslope at an angle of -10 to 5 degrees. Upslope installation is for incline screens that the outlet is higher than the inlet. Downslope installation is for incline screens that the inlet is higher than the outlet.

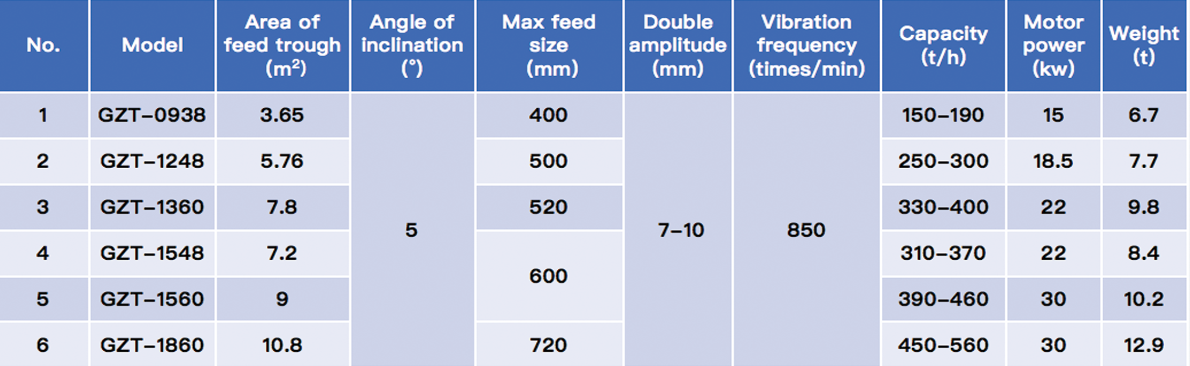

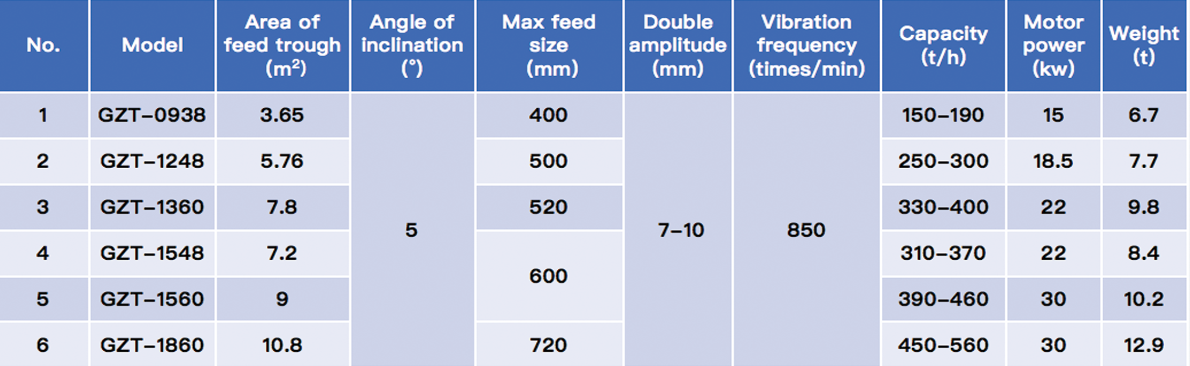

Main Technical Parameters of GZT Series Grizzly Feeder

Note:

1. Parameters in the table may vary based on parts selected and distinct customer requirements. Actual parameters in final drawings prevail.

2. The capacity varies on the basis of materials, feed sizes and other factors.

Contact Us

If our product don't have your specifications,

our custom shop can give you an unique solution to meet your needs

Custom Shop